Starter Motors - A Brief History Lesson

The first automotive electric starters were inertia drive units, these “inertias” lasted in one form or another until well into the 1960's. To operate, inertia drive starters rely on the acceleration of the starter armature to throw the pinion into mesh with the ring gear. As the pinion is spinning prior to engagement a certain amount of gear clash is inevitable, and premature pinion and ring gear failure is usually the result.

Because of this design the gear pitch needed to be rather coarse to enable engagement. This coarse pitch didn't allow for favourable pinion to ring gear ratios to start the more modern, shorter stroke, higher compression engines that were being built.

The development of pre-engaged starter motors began as modern engine designs demanded a better system. The pre-engaged starter allows for the use of finer gear pitches and taller gear ratios for similar ring gear diameters. In a pre-engaged starter the pinion engages in the ring gear as the solenoid is energised and then as the solenoid contacts close the starter armature receives battery power and begins to rotate, starting the engine.

As engine capacity and compression ratios continued to increase so did the demand on the starter, as more horsepower was needed to start the engine the larger the starter need to be. Enter the “gear reduction starter”.

The gear reduction starter was first used in automotive mass production by Chrysler in 1962. These starters were still big and heavy but provided just enough torque to wind over the very high compression large displacement engines Chrysler was starting to build at that time. Gear reduction starters feature a reduction in gear ratio between the armature and the pinion gear of anywhere between 2.5 and 4.5:1, and the armature is designed to rotate at a higher speed when energised by the solenoid. Pinion speed remains the same as in a conventional pre-engaged starter but the cranking torque of the gear reduction starter is greatly enhanced.

In the late 1970's Japanese manufacturers started to introduce a limited range of gear reduction starters of their own design. They were smaller, lighter and incredibly reliable. The US aftermarket recognized their potential and the first “aftermarket” gear reduction starters using Japanese technology were produced.

All gear reduction starters are not created equal

Every automotive manufacturer now fits a version of the gear reduction starter to their vehicles as original equipment. There are 3 basic designs and they are all used by the aftermarket, but they are not all created equal!

The first is the OSGR (outside gear reduction) Fig A, where the armature engages with the pinion clutch hub. These starters mostly have steel gears and 4 roller bearings and a reduction of around 3-3.5:1, are rated at 1.2-2.0kw and have around 250-300 ft/lb's of torque.

Photo above: Fig A

The second is the PLGR (planetary gear reduction) Fig B, where the armature (sun gear) runs inside “planet” gears which in turn run around inside an annulus gear. These starters have a reduction of between 4-6:-1. Generally, the lower numeric ratios use plastic annulus gears whereas some of the higher ratio models utilise steel. Most PLGR starters use “permanent magnet” fields and are rated at

1.2-1.6kw with 160-220 ft/lb's of torque.

Photo above: Fig B

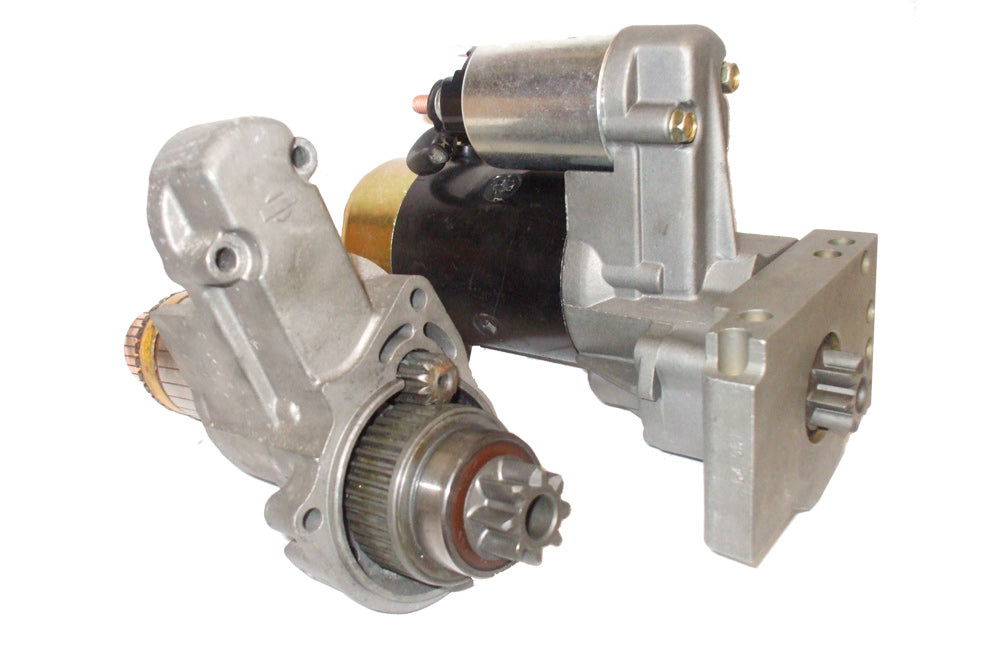

The third type is the Denso gear reduction starter used by “Roadrunner starters” Fig C. The addition of an “idler” gear between the armature and the pinion clutch hub multiplies the torque produced dramatically. These Denso starters have steel gears and 5 roller bearings, a reduction of around 4.5:1, are available between 1.0 and 2.2kw and have 450-500 ft/lb's of torque.

Photo above: Fig C

Beware of counterfeits

Nobody copies a bad idea so be wary of illegal, pirated and counterfeit versions of aftermarket components. Sometimes it's hard to tell if you're buying OEM quality so ask your supplier up front where the goods are made. If the item is heavily discounted, has dubious advertising or improbable ratings and specification or comes with a lack of technical information it's probably a “knock off”!